When it comes to safety, we never compromise-

all the materials that used in our diaper production process need to be 100% safe and of high quality.

That’s why we strictly control our raw materials.

How many types of materials do we inspect?

There are 3 types of materials that need to be carefully checked before entering to our warehouse.

1. Raw materials: including SAP, wood pulp, core, paper, non-woven, fluffy non-woven, dust-free paper, spunlace non-woven, meltblown non-woven, frontal tape, bands, corn film, aloe, etc..

2. Auxiliary materials: including polybag, carton, sticker, tape, bubble bag, etc..

3. Advertisement materials.

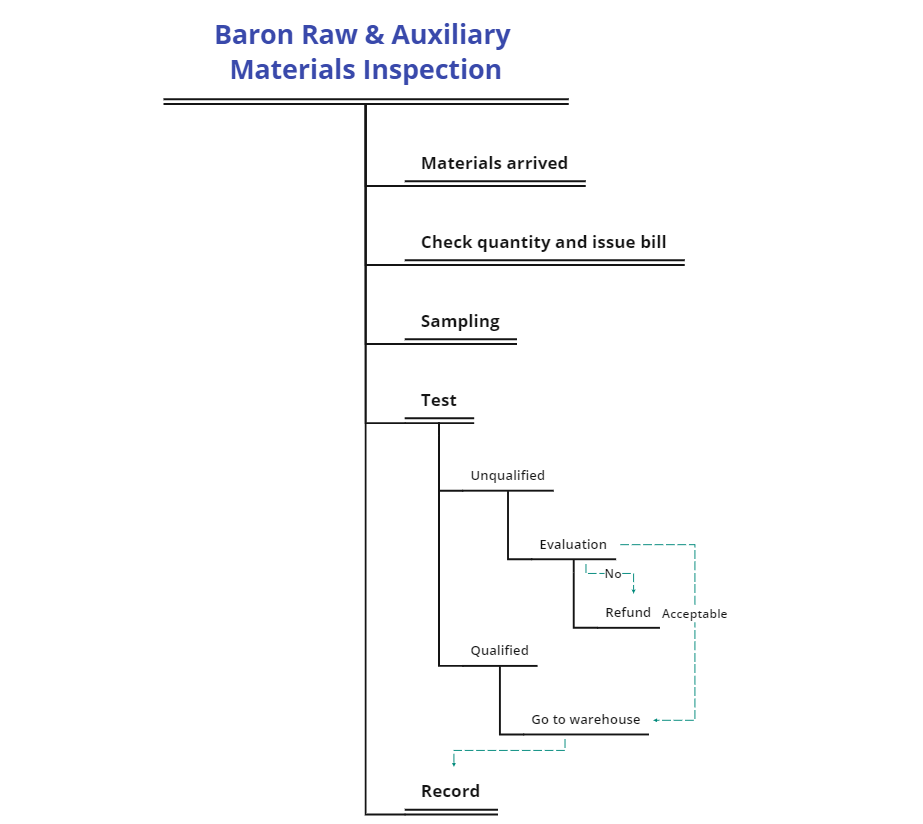

How do we inspect the quality of the materials?

Every batch of materials, Baron QC(Quality Control Department) needs to check its appearance, weight, stretch ability, PH, fluff level, hygiene date(bacterial, fungus, coli), air permeability, absorbent magnification, absorbing speed, hydrostatic pressure resistance, solvent reside, odor, etc.,

which follows the standard QC steps:

Product quality largely depends on the quality of raw materials and is one of the important factors affecting product quality.

Therefore, we must strengthen the inspection of incoming raw materials, strictly control the incoming customs,

and ensure that the incoming raw materials meet the specified requirements.

This is the first step for us to return your trust!